Preliminary results of the project

- Composite Metal Polymer (CMP) coatings show maintained non-stick function after heavy erosion during testing at room temperature.

- CMP coatings may remain intact after one-year field exposure at certain boiler positions. Regarding testing on a flue gas fan the non-stick properties remain after 3 firing seasons.

- CMP coatings show great potential for preventing fouling at some parts of CHP and thermal heating plants

Is there something, some results, that has emerged during the project that you did not expect?

Composite Metal Polymer (CMP) coatings should be tested on larger surfaces to prevent general overgrowth of deposits, since these has a tendency to overgrow the test samples as well, which does not give a correct picture of the possibility of CMP to prevent fouling.

Name of PhD students, project participants and project leader of project

Matti Huhtakangas, MH Engineering AB, project leader.

Ragna Elger, Swerea KIMAB, researcher, previous PhD student in the project, thesis defended 03/06/16.

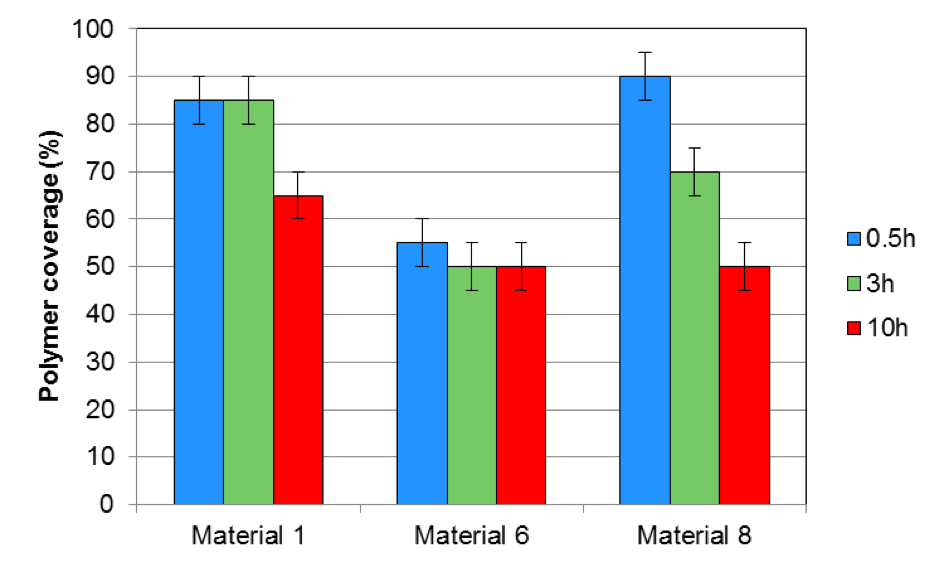

Results after laboratory wear tests

Material 1: PTFE

Material 6: PTFE mix

Material 8: Silicon

Field exposure at Öresundskraft Vesthamnverken. CMP samples after one firing season in the cone under the electrostatic precipitation filter.

List the companies that participate in the project

MH Engineering AB.

Swerea KIMAB.

Öresundskraft, Vesthamnverken.

Dong Avedöre