KME focused on developing material technology to create maximum efficiency for energy conversion of renewable fuels and waste. KME had its sights firmly set on continuing to raise the efficiency of long-term sustainable energy as well as ensuring international industrial competitiveness.

Because the challenge of implementing environmentally sustainable energy was both complex and vital, the KME consortium is financed by the Swedish Energy Agency together with stakeholders from the energy industry, manufacturers of systems and components for energy conversion and material producers.

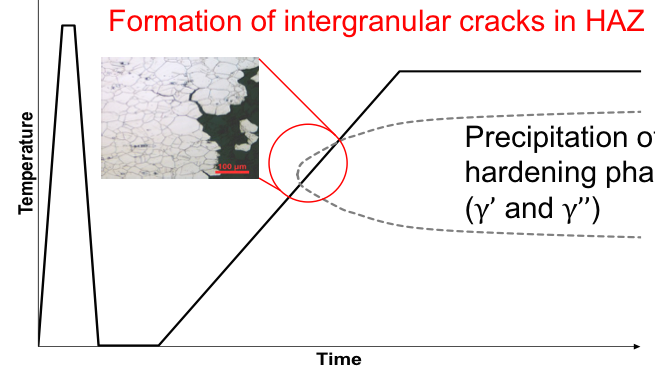

The programme was operated and managed by Energiforsk. During the programme period of 2018 and 2022, five industry-relevant projects were conducted. The projects covered a wide range of research areas, such as the mechanical behaviour and corrosion of various materials in different high-temperature environments, as well as the performance of different coating materials.

The Swedish translation of KME: Konsortium Materialteknik för Termiska Energiprocesser.